- FUNCTION

- PERFORMANCE

- HIGH VISCOUS PUMPING

- SKIMMER OFFLOADING

- TRANSPORT

- Amphibian tool carrier

- OIL SPILLS

- Beach Cleaning

- SUBMERGED OIL RECOVERY

- Oil in ice

- Chemical spills

- TANK CLEANINGÂ Â Â Â

- Industry

- Pulp and paper industry

- Chemical industry

- Machine tool waste

- Ship loading arm

- DREDGING

- Algae bloom

- HOME

- News

- Downloads

- Company

- Contact

High viscous pumping

|

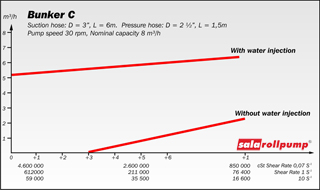

A series of pump tests were conducted to measure the suction capability of the Salarollpump with high viscous oil. The suction nozzle was placed into approximately 1m3 (264 gallons) of bunker C oil. The suction lift was 0.6 m (2 ft) and a 6 m (20ft) length of 3" suction hose was used. The discharge hose was 2 1/2" and 1.5m (5 ft) in length. The pump speed can be set at 15, 30 or 45 rpm. The medium speed of 30 rpm was selected which gives a nominal capacity of 8 m3/hr (35 gpm). Tests were conducted at three different temperatures; 1, 5 and 10°C (33.8, 41 and 50°F). The viscosity in cSt is shown in the diagram at three different shear rates. The pour point of the oil was 18°C (64.4°F).  |

The tests were carried out with and without water injection in the suction nozzle. The results indicate that the limit without water injection was approximately 3,500,000 cSt at shear rate 0.07 S-1. With water injection the capacity was increased to approximately 65% of the nominal capacity at a viscosity around 4,500,000 cSt with the same shear rate of 0.07 S-1. Preliminary tests not illustrated below were also conducted with diesel oil injected into the suction nozzle instead of water. The preliminary test results indicate an improved capacity but not as much as with water.  |

VIDEO |

|

English

English Russian

Russian